Producing systematically

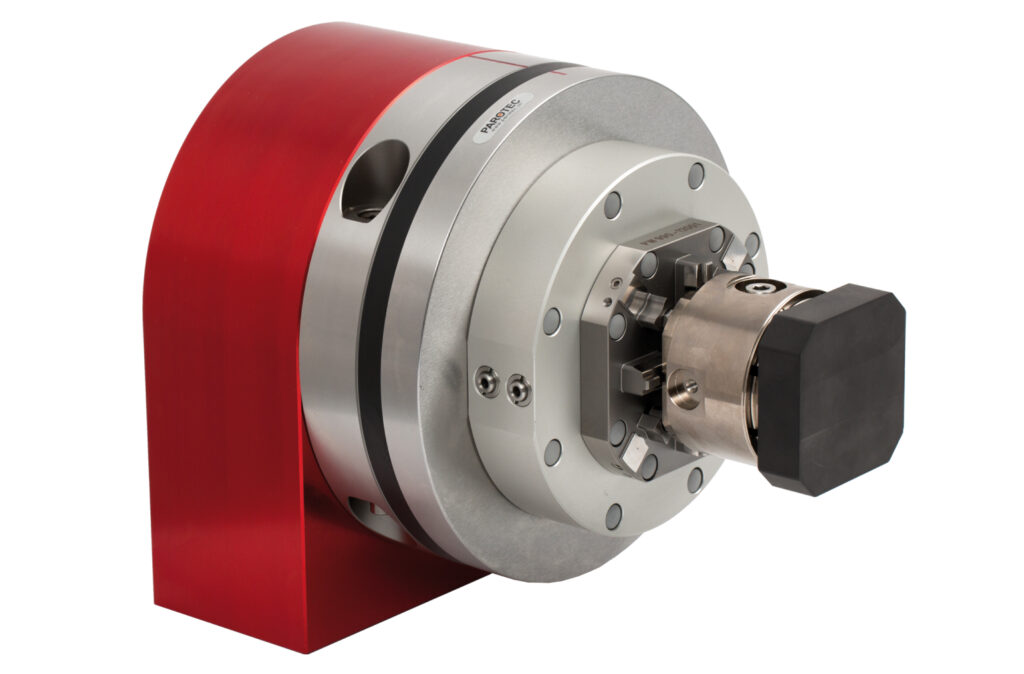

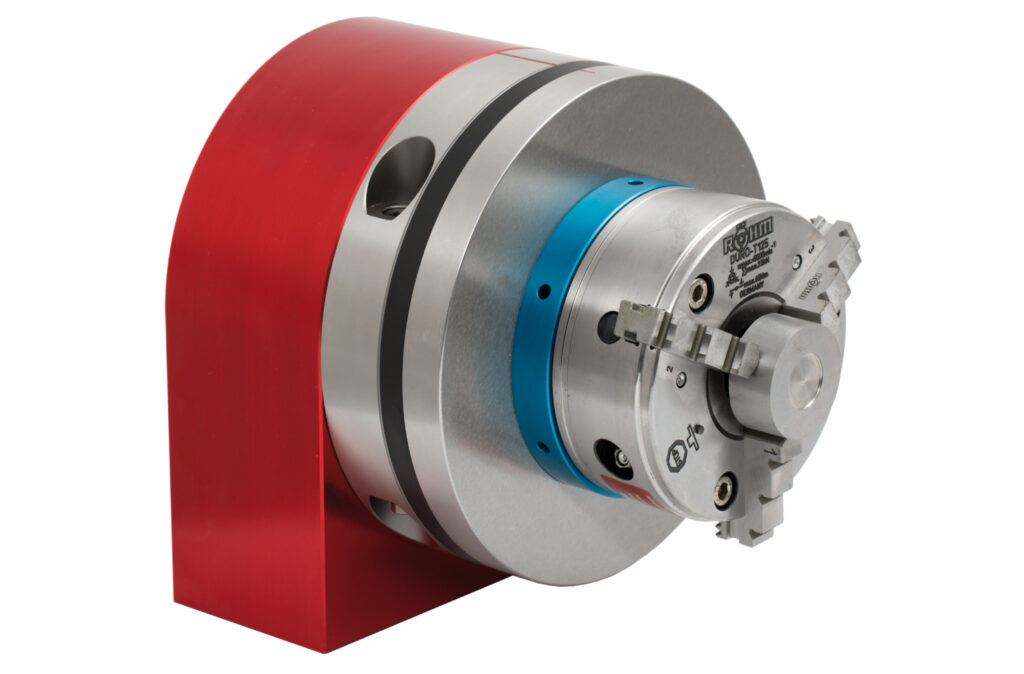

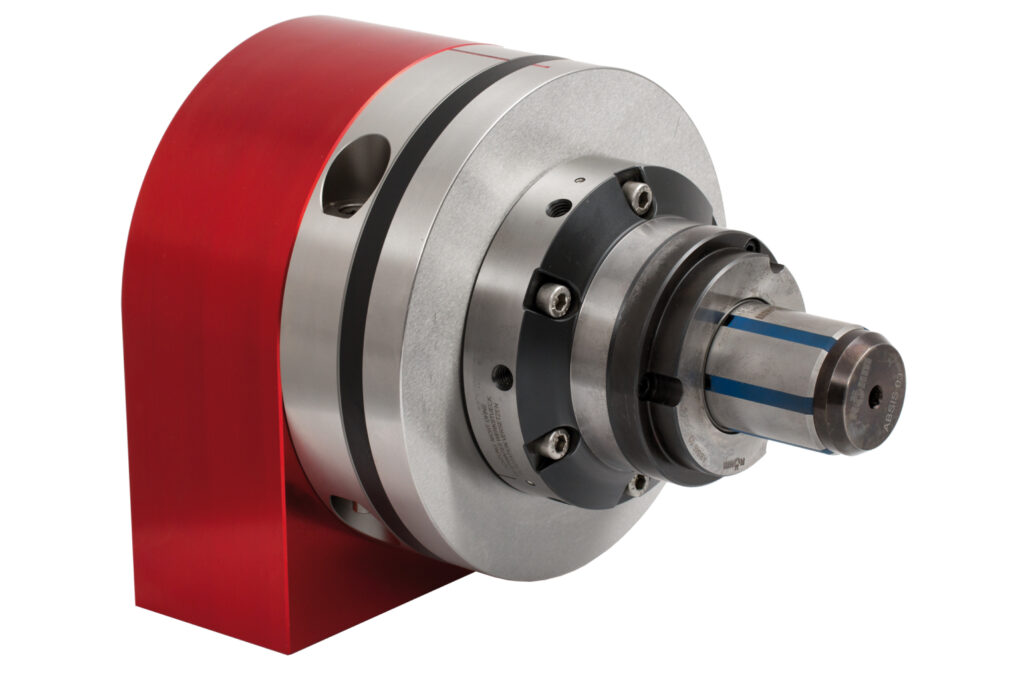

The palletizing system for rotative machining.

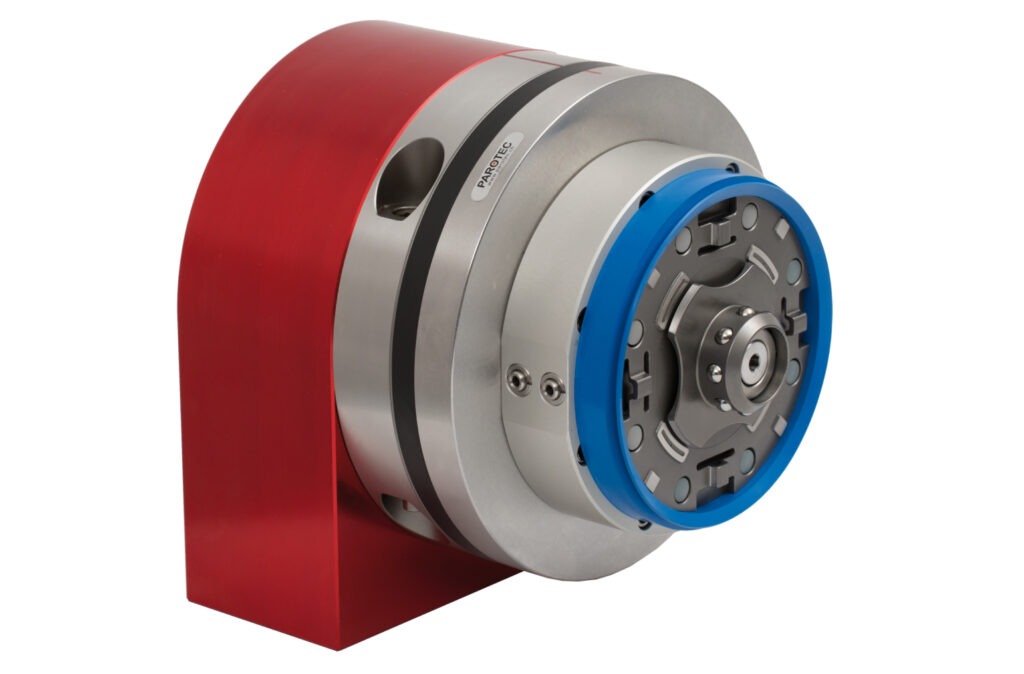

With ROTO GRIP

different spindle connections are standardized to a common denominator. This allows you to produce faster, more flexibly, and more efficiently. By simplifying the connection process, you can easily adapt to various machining tasks, streamline your operations, and enhance overall productivity in your manufacturing processes.

Without ROTO GRIP

each machine remains a separate entity, requiring its own specific clamping tools. This situation leads to significant costs, as you must invest in a variety of tools for different machines. The lack of standardization results in inefficiencies and complications, making it challenging to adapt to changing production needs and increasing overall operational expenses.

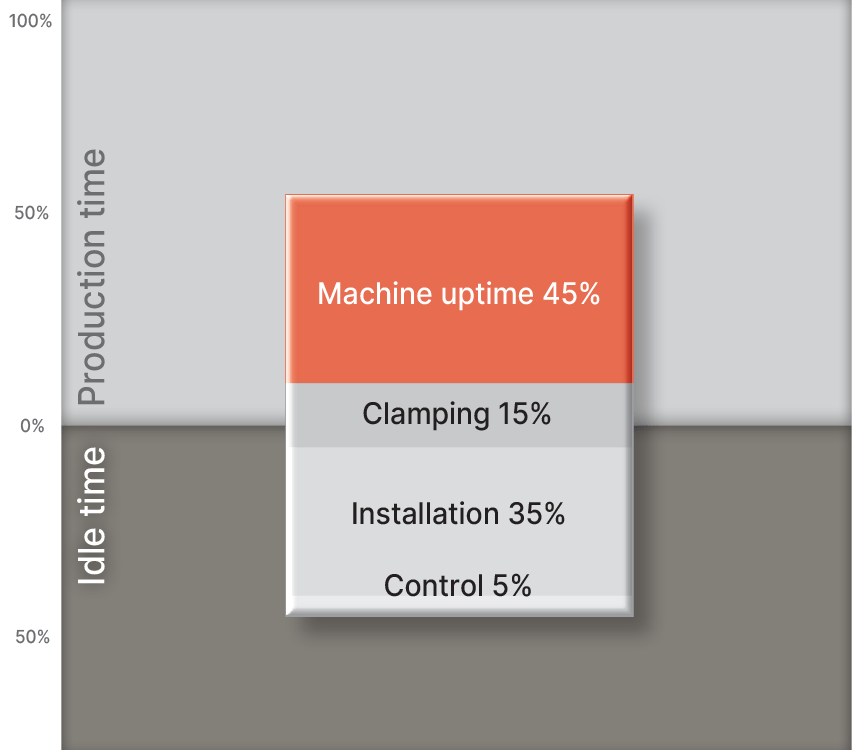

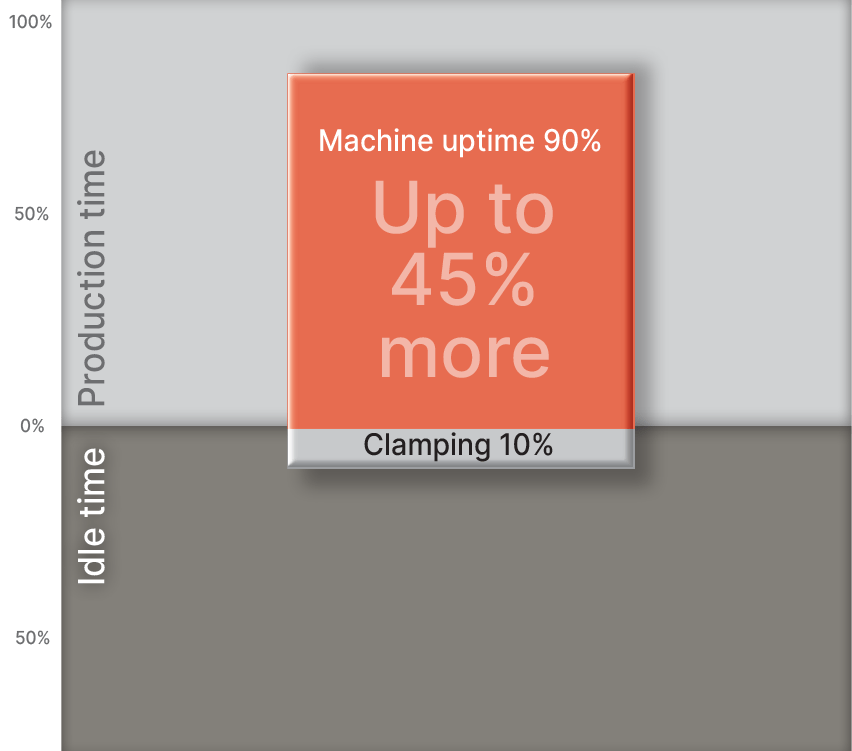

Up to 45% more efficiency

- Uneconomic manufacturing

- Non-optimized manufacturing processes

- No standardization

- High costs per unit

- Excessive delivery times

- Unfulfilled delivery dates

- High error rate

- Pricing pressure and competitive pressure

- Higher productivity and income

- Optimized manufacturing processes

- Standardized interfaces

- Low unit costs

- Reduced delivery times

- Adherence to delivery dates

- Low error rate

- Competitive capacity

The flexible palletizing system for rotative machining.

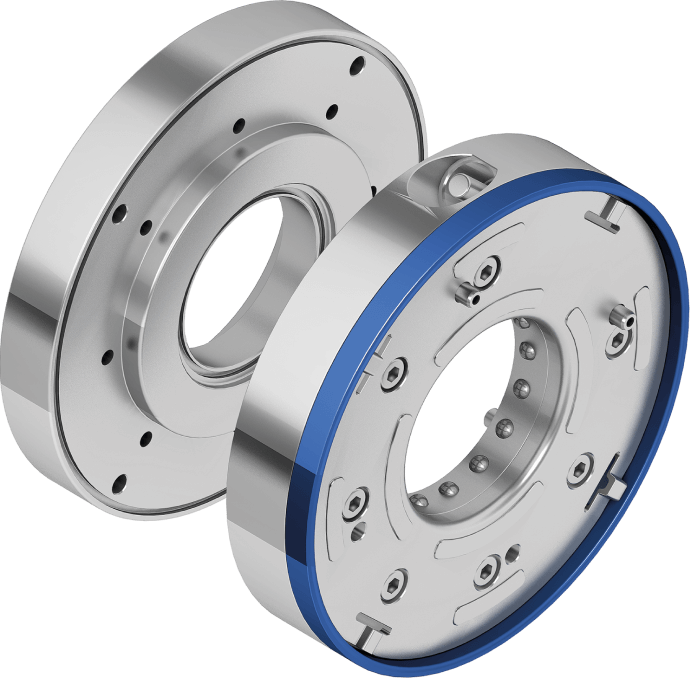

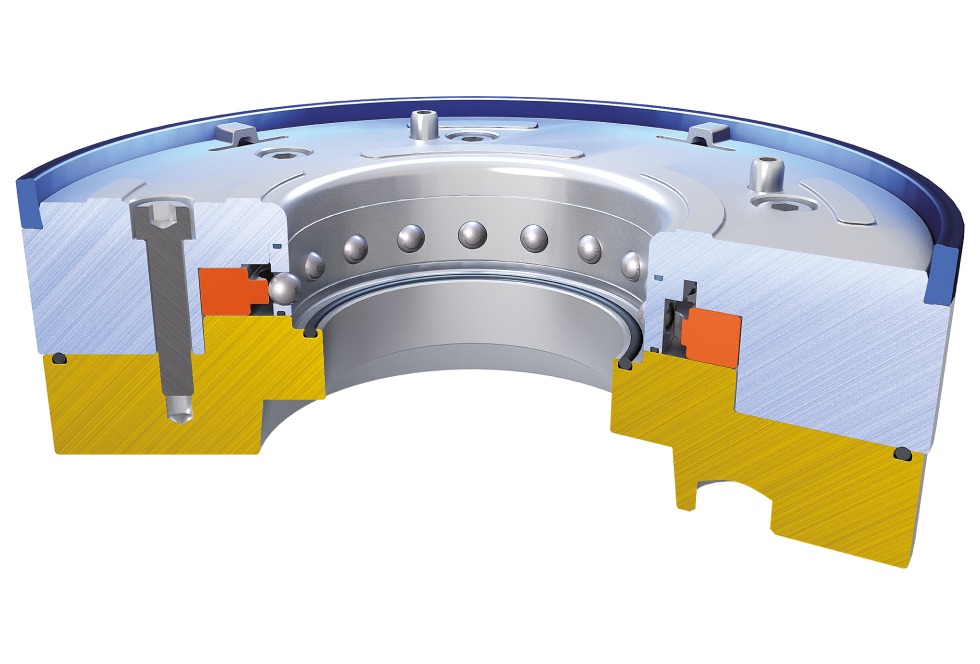

The Technology

By using the suitable adapter plate (yellow), all the different spindle adapters can be standardized to a common denominator. This allows for greater flexibility and compatibility across various systems, making it easier to interchange components and optimize the setup for different machining tasks.

Clamping and releasing is carried out manually. During the fastening of ROTO GRIP, you can hear the fastening screw of the clamping mechanism latch into place. This audible feedback ensures that the clamping is secure, providing confidence in the reliability of the setup.

Who changes will profit.

The consequences: The aquisition costs for your tensioning means will be reduced. Your flexibility and your competitiveness will increase.

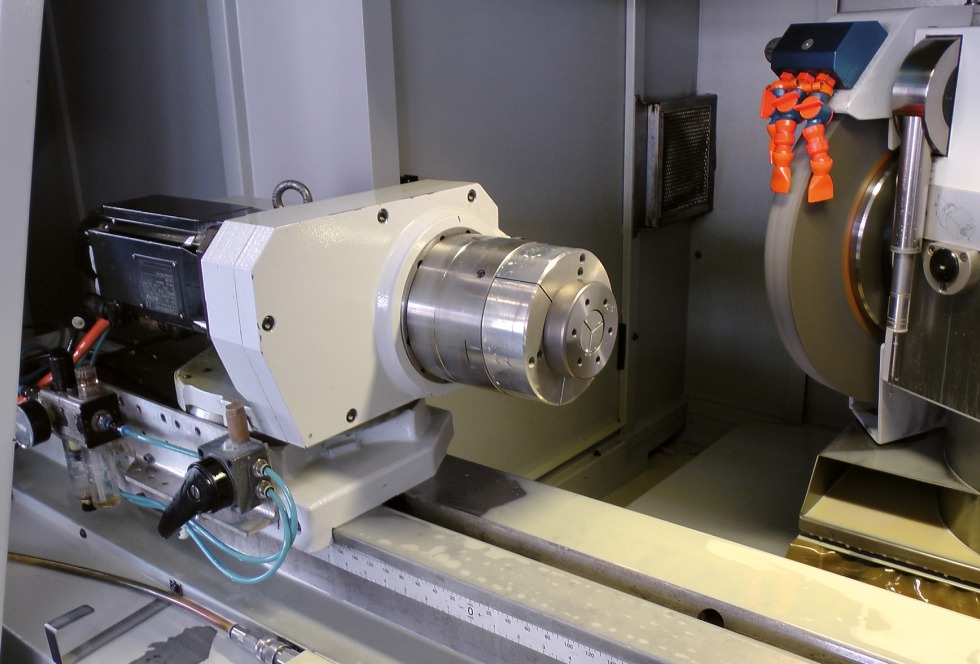

Turning machine without ROTO GRIP

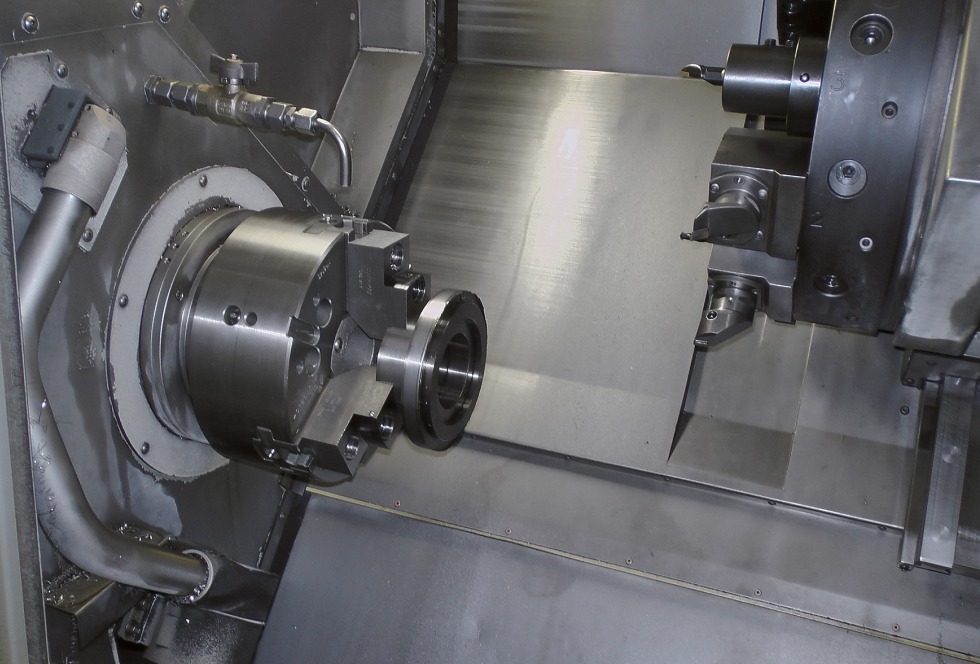

Grinding machine without ROTO GRIP

A great many of possibilities.

Download Brochure